Lean manufacturing can be a valuable tool for a distressed business, as it focuses on identifying and eliminating waste and improving efficiency. By doing so, it can help businesses reduce costs, improve quality, and increase productivity, which can be critical for companies facing financial challenges.

Here are some ways that lean manufacturing can assist a distressed business:

- Cost reduction: By identifying and eliminating waste, distressed businesses can reduce costs associated with excess inventory, overproduction, waiting times, and defects. This can help to free up cash flow and improve the financial health of the business.

- Quality improvement: Distressed businesses may be facing quality issues, which can lead to increased costs associated with rework, warranty claims, and customer returns. Lean manufacturing can help to improve quality and reduce these costs.

- Increased productivity: Distressed businesses may be struggling with low productivity and throughput, which can limit their ability to meet customer demand and generate revenue. Lean manufacturing can help to streamline production processes and increase throughput, allowing businesses to produce more with fewer resources.

- Employee engagement: Lean manufacturing involves a culture of continuous improvement and employee involvement, which can help to improve morale, job satisfaction, and retention. This can be particularly valuable for distressed businesses, as engaged and motivated employees can help to drive the company’s turnaround.

- Process improvement: Distressed businesses may be facing challenges with outdated or inefficient processes, which can limit their ability to compete in the marketplace. Lean manufacturing can help to identify and eliminate these inefficiencies, allowing businesses to operate more effectively and efficiently.

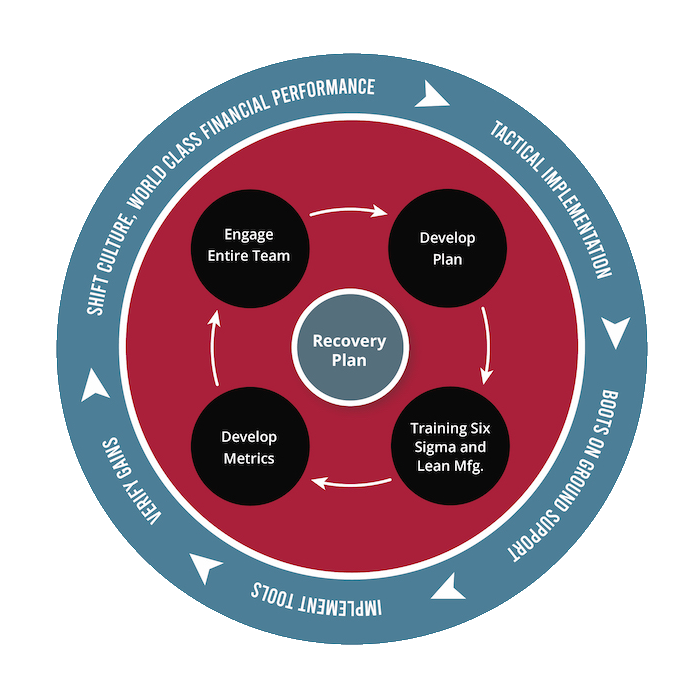

Overall, lean manufacturing can be a valuable tool for distressed businesses looking to improve their financial health and competitiveness. However, it is important to note that implementing lean manufacturing requires a significant upfront investment in time, resources, and training, so companies should engage Lean Manufacturing and Lean Six Sigma Experts to carefully evaluate the costs and benefits before proceeding.

GKW Business Solutions has the experience to facilitate and implement Lean Manufacturing and Six Sigma Tools in your business.

1Work with Management to Develop Recovery Plan

Clear tactical approach

2Assist with Implementation of Recovery Plan

Support for the outlined solutions

3Provide Training

Build a tool box

4Develop and Implement Reporting and Metrics

Verify and validate improvements

Company of Professionals

Mike and Will are here to help ease your pain points. Let us know how we can help!