Kata refers to structured routines and patterns of behavior aimed at continuous improvement and learning. Specifically, kata in this context is part of a method popularized by Mike Rother in his book Toyota Kata, which focuses on developing scientific thinking and continuous improvement within an organization.

In Lean, there are two main types of kata:

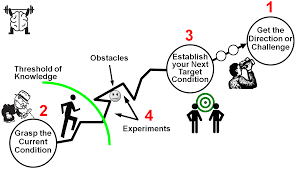

- Improvement Kata: This is a routine that helps employees at all levels of an organization practice and develop problem-solving and continuous improvement skills. The process follows a systematic cycle:

- Understand the direction or challenge: Set a long-term vision or goal.

- Grasp the current condition: Analyze and understand the current state of the process or system.

- Establish the next target condition: Define a near-term target that will move you toward the long-term goal.

- Conduct experiments (PDCA cycles): Implement small changes through Plan-Do-Check-Act (PDCA) cycles to gradually improve the process.

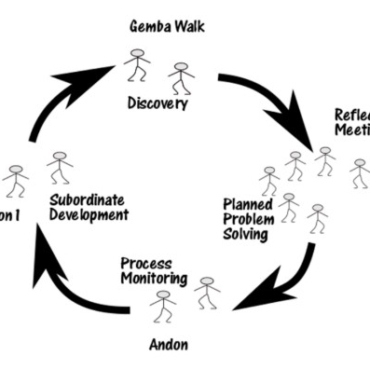

- Coaching Kata: This refers to a structured approach to teaching and reinforcing the Improvement Kata. It involves a mentor or coach guiding a learner through the improvement cycles, helping them practice and internalize scientific problem-solving techniques. The coach asks guiding questions to help the learner develop their thinking, rather than giving direct instructions.

The use of kata in Lean is inspired by Toyota’s approach to continuous improvement (kaizen) and problem-solving. By practicing these routines, organizations can foster a culture of continuous learning and improvement, where employees develop the mindset and skills to tackle challenges systematically.

So how can KATA help your business?

1. Fosters Continuous Improvement:

Kata encourages employees to continuously identify opportunities for improvement, experiment with solutions, and refine processes. This constant pursuit of incremental improvements helps a business stay agile, reduce waste, and improve efficiency over time.

2. Develops a Problem-Solving Culture:

Kata routines train employees to approach problems scientifically using Plan-Do-Check-Act (PDCA) cycles. Over time, this structured approach to problem-solving becomes second nature, leading to more effective and sustainable solutions, rather than quick fixes or reactive firefighting.

3. Enhances Employee Engagement:

When employees are empowered to identify challenges and take ownership of improvements, they feel more valued and engaged. The coaching aspect of kata also fosters collaboration between leaders and teams, helping employees grow their skills and feel more connected to the business’s success.

4. Builds Organizational Agility:

Kata routines help businesses become more adaptable to change. By practicing small, iterative cycles of improvement, organizations can quickly pivot, experiment with new ideas, and respond to market or operational changes in a structured and manageable way.

5. Improves Process Consistency and Quality:

Through continuous experimentation and refinement, kata helps to reduce variability and improve the consistency of processes. This leads to higher quality outputs, fewer defects, and better customer satisfaction, which ultimately enhances the company’s competitiveness.

6. Reduces Waste (Lean Principles):

By using kata to regularly assess and improve processes, companies can identify and eliminate forms of waste, such as time inefficiencies, excess inventory, and unnecessary movements. This results in lower costs and a more streamlined operation, which is a core principle of Lean Manufacturing.

7. Develops Leadership Skills:

The Coaching Kata focuses on developing leaders who mentor and guide their teams in continuous improvement practices. This not only strengthens leadership but also ensures that the organization can sustain improvements and develop a culture of learning.

8. Aligns Goals with Action:

Kata starts by defining a long-term vision and breaking it down into smaller, achievable goals (target conditions). This ensures that day-to-day activities are aligned with the company’s strategic objectives, creating a clearer focus and more purposeful work across all levels of the organization.

9. Encourages Innovation:

The structured experimentation process embedded in kata encourages teams to try out new ideas in small, low-risk ways. This fosters a mindset of innovation, where employees are not afraid to test new approaches and learn from failures, ultimately driving breakthrough improvements.

10. Sustains Long-Term Success:

By embedding the routines of kata into everyday work, businesses can sustain a culture of improvement and scientific thinking over the long term. This prevents the typical decline in performance that can happen after short-lived improvement initiatives, ensuring that gains are sustained and built upon.

Summary of Kata Benefits:

- Continuous improvement and innovation

- Structured, scientific problem-solving

- Enhanced employee engagement and leadership

- Waste reduction and efficiency

- Agile, adaptive operations

When kata becomes part of a company’s DNA, it creates a resilient, learning organization capable of thriving in changing environments while continuously improving its operations.