Poka-yoke is a Japanese term that means “mistake-proofing” or “error-proofing.” It is a lean manufacturing technique aimed at preventing errors or defects in processes. Developed by Shigeo Shingo as part of the Toyota Production System, poka-yoke ensures that mistakes are either avoided entirely or immediately detected and corrected.

Key Concepts of Poka-Yoke:

- Prevention Over Correction: The focus is on preventing errors before they occur rather than fixing them afterward.

- Simplicity: Solutions are often simple and low-cost.

- User-Friendly Design: Incorporates intuitive mechanisms that make it easy to avoid mistakes.

Types of Poka-Yoke

- Control Poka-Yoke:

- Prevents a process from starting or continuing if an error condition exists.

- Example: A microwave won’t run unless the door is closed.

- Warning Poka-Yoke:

- Alerts the user to potential errors using signals like alarms, lights, or displays.

- Example: A car beeps when the seatbelt isn’t fastened.

Methods of Poka-Yoke Implementation

- Physical Constraints: Mechanisms that prevent incorrect actions.

- Example: USB drives can only be inserted one way.

- Guide Tools: Templates, jigs, or fixtures that ensure proper assembly or alignment.

- Example: Stencils for precise drilling.

- Error Detection: Sensors or systems that identify mistakes.

- Example: Spell-check in word processors.

- Checklists: Ensure all necessary steps are completed before proceeding.

- Example: Pre-flight checklists in aviation.

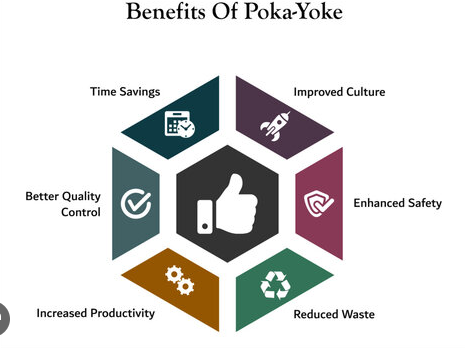

Advantages of Poka-Yoke

- Error Prevention:

- Reduces human errors by designing processes that are inherently mistake-proof.

- Improved Quality:

- Fewer errors lead to higher product or service quality, increasing customer satisfaction.

- Cost Reduction:

- Preventing defects reduces waste, rework, and the cost of corrective actions.

- Efficiency:

- Processes become more streamlined as error-checking and corrective steps are minimized.

- Enhanced Safety:

- Reduces risks by avoiding dangerous errors, especially in high-risk environments.

- Employee Empowerment:

- Creates a work environment where employees are less likely to make errors, leading to higher morale and productivity.

- Compliance and Standardization:

- Ensures adherence to standards and regulatory requirements.

- Scalability:

- Effective poka-yoke mechanisms can be scaled across different processes or industries.

Real-World Examples of Poka-Yoke

- Manufacturing:

- Color-coded parts to ensure correct assembly.

- Healthcare:

- Barcoding systems to match patients with their prescribed medications.

- Technology:

- Auto-save features in software to prevent data loss.

- Consumer Products:

- Automatic shut-off in irons to prevent overheating.

- Retail:

- POS systems that alert cashiers when incorrect pricing is entered.

By integrating poka-yoke, organizations can ensure more reliable operations, enhance customer trust, and foster a culture of continuous improvement.

GKW Business Solutions Offers a Two Day Workshop on Poka-Yoke, contact us for the details TODAY!

GKW Website