SMED, or Single-Minute Exchange of Dies, is a methodology for reducing the time it takes to switch from one production process or product to another. While it originated in manufacturing, its principles can be applied to various types of businesses. Here’s how SMED might benefit your business:

- Increased Efficiency: By minimizing changeover times, SMED can help you maximize production time and reduce downtime. This means more efficient use of equipment and resources.

- Improved Flexibility: Faster changeovers allow you to be more responsive to customer demands and market changes. You can quickly switch between different products or services based on current needs.

- Reduced Inventory Costs: With shorter changeover times, you can maintain lower levels of inventory, reducing holding costs and minimizing the risk of obsolescence.

- Higher Productivity: With less time spent on changeovers, your production or service operations can achieve higher overall productivity and output.

- Enhanced Quality: SMED encourages standardizing and streamlining processes, which can lead to more consistent quality and fewer defects.

- Better Resource Utilization: Reducing the time equipment is idle means that resources like labor and machinery are used more effectively, leading to cost savings.

- Improved Employee Morale: Simplified processes can reduce the complexity of tasks, making work easier and more engaging for employees.

- Cost Savings: Reduced downtime and increased efficiency can lead to lower production costs and better financial performance.

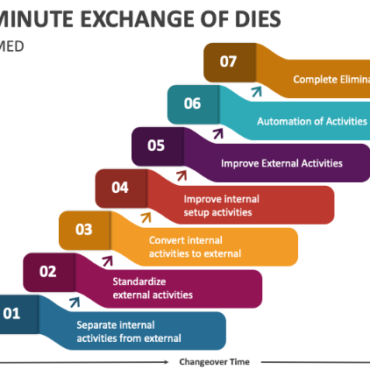

Implementing SMED typically involves analyzing your current changeover processes, identifying and eliminating waste, and standardizing procedures. The approach often includes separating internal (during production) and external (while not in production) setup tasks, simplifying and streamlining steps, and using tools and techniques to make changeovers faster and more efficient.

Overall, applying SMED principles can help your business become more agile, cost-effective, and competitive.