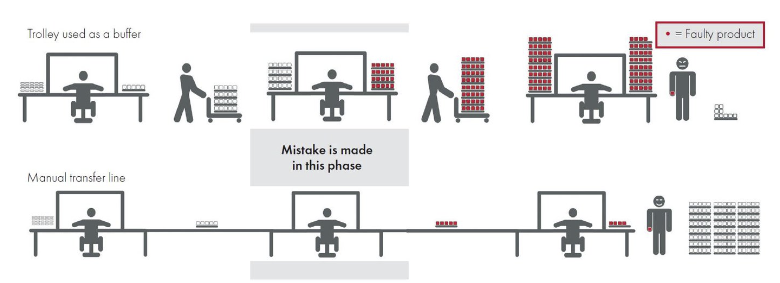

One-Piece Flow is a lean manufacturing concept that is aimed to achieve a discrete flow of work contrary to ‘batch’ production approach. In simple terms, it means one-by-one processing of a product. A single unit of product flows between different processes. It follows the old adage – ‘One step at a time’. As there is just one unit flowing – there is no wait time in between processes. One-piece flow is also known as Continuous-Flow Processing or Single-Flow Processing.

It is closely associated with the Just-in-time system popularized by Toyota. It requires continuous examination and improvement of the production line that eventually leads to lower costs, reduction of waste, and error-free output.

Example Video of “One Piece Flow”

https://getbreakout.com/blog/what-is-one-piece-flow/