Implementing Six Sigma Black Belt training in a manufacturing organization can yield significant benefits across various aspects of the business. Here’s a detailed report outlining the value it brings:

1. Quality Improvement:

- Six Sigma Black Belt training focuses on reducing defects and improving process efficiency. By applying statistical methods and problem-solving techniques, Black Belts can identify root causes of defects and implement solutions to eliminate them.

- Improved quality leads to higher customer satisfaction, reduced rework, and fewer product returns, ultimately enhancing the organization’s reputation and competitiveness.

2. Cost Reduction:

- Six Sigma emphasizes cost reduction through the elimination of waste and variation in processes. Black Belts are trained to identify inefficiencies and optimize processes to minimize resource usage.

- By streamlining operations and reducing defects, organizations can realize significant cost savings in materials, labor, and overhead expenses.

3. Enhanced Efficiency:

- Black Belts are equipped with tools and methodologies to analyze and improve process flow, leading to increased productivity and throughput.

- By reducing cycle times and improving lead times, organizations can respond more effectively to customer demands and market changes, thereby gaining a competitive advantage.

4. Data-Driven Decision Making:

- Six Sigma emphasizes data-driven decision-making based on rigorous analysis and measurement. Black Belts are trained to collect and analyze relevant data to support decision-making processes.

- Data-driven insights enable organizations to identify trends, anticipate problems, and make informed decisions to drive continuous improvement and strategic planning.

5. Employee Development:

- Six Sigma Black Belt training not only enhances the skills of individuals but also fosters a culture of continuous improvement within the organization.

- Through training and hands-on project experience, Black Belts develop leadership, communication, and problem-solving skills, which can have a positive ripple effect on team performance and morale.

6. Customer Focus:

- Six Sigma places a strong emphasis on understanding and meeting customer requirements. Black Belts are trained to incorporate customer feedback into process improvement initiatives.

- By aligning processes with customer expectations, organizations can enhance customer satisfaction, loyalty, and retention, leading to long-term business success.

7. Risk Mitigation:

- Six Sigma methodologies help organizations identify and mitigate risks associated with process variability and uncertainty.

- By proactively addressing potential risks and implementing robust control measures, organizations can minimize the likelihood of quality issues, compliance breaches, and other operational disruptions.

8. Compliance and Standards Adherence:

- Six Sigma promotes adherence to quality standards and regulatory requirements. Black Belts ensure that processes are compliant with industry regulations and standards.

- Compliance with standards not only ensures product quality and safety but also reduces the risk of legal and financial penalties associated with non-compliance.

Conclusion:

- Six Sigma Black Belt training offers tangible benefits to manufacturing organizations, including improved quality, cost reduction, enhanced efficiency, data-driven decision-making, employee development, customer focus, risk mitigation, and compliance.

- By investing in Black Belt training and implementing Six Sigma methodologies, organizations can achieve sustained improvements in performance, profitability, and competitiveness in today’s dynamic business environment.

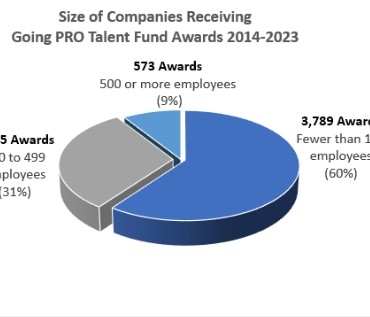

GKW Business Solutions Is Currently Offering Six Sigma Certification Classes, Winter Classes Are Filling Quickly.