Recently we at GKW Business Solutions were engaged to assist with reducing waste in a high-volume manufacturing process, specifically excessive scrap. As a Six Sigma Lean Organization my partner decided to use Design of Experiments to understand how the process variable (10+) was impacting throughput of the process. The DOE tool identified the settings for the variables that were impacting scrap reducing waste by 65%. More importantly the Team was trained on how to use the process in the future.

Below is more on the DOE Process:

Design of Experiments (DOE) is a statistical method used to plan and conduct experiments to optimize processes, improve product quality, and reduce costs.

The key idea behind DOE is to identify the important variables that affect the outcome of an experiment, and then design a set of experiments that systematically vary these variables while holding all other variables constant. By doing so, the experimenter can identify which variables have the greatest impact on the outcome, and how they interact with each other.

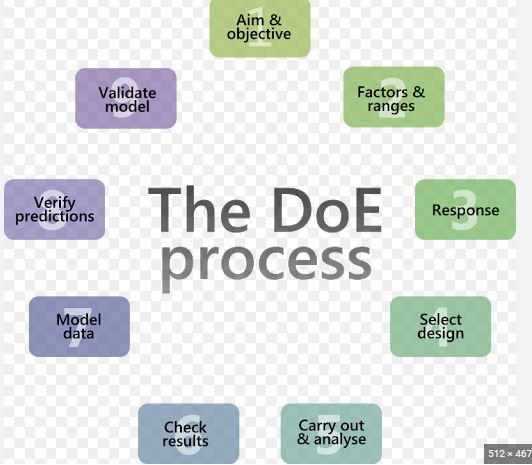

The basic steps in DOE are:

- Define the problem: Identify the objective of the experiment and the response variable(s) to be measured.

- Choose the factors: Identify the independent variables (factors) that may affect the response variable.

- Determine the levels: Determine the levels of each factor that will be used in the experiment.

- Design the experiment: Choose an appropriate experimental design (such as a factorial design or a response surface design) to systematically vary the factors and collect data.

- Conduct the experiment: Conduct the experiment according to the design.

- Analyze the data: Analyze the data to identify the significant factors and their interactions.

- Draw conclusions: Draw conclusions based on the results of the analysis and use the information gained to improve the process or product.

DOE is widely used in a variety of industries, including manufacturing, engineering, and healthcare, to optimize processes, improve product quality, and reduce costs.

Contact Will Craig at GKW Business Solutions on how DOE can improve Root Cause and Corrective action within your organization.